Look!

You can email me and ask me questions at...

Unknown_ak@hotmail.com

Battlebot building

A lot of new builders are looking for good motors. Well, my friends at National Power Chair have two wheelchair motor lines for sale. The first is great for middleweights and heavyweights and the second is an awesome deal for lightweights and middleweights.

The first motor (NPC-60522) costs each.

The 60522 is up from to per motor. National Power Chair was able to sell them initially at the lower price because they had some "line rejects" that worked perfectly well. Now they have to rebuild the motors they have left. More labor, more money. They still are a bargain since the same motor rebuilt at retail for a person in a chair (to a much higher noise standard) is .

General specs are

24 volts (good)

70 amps peak, 14 amps continuous (use a Vantec RDFR23 speedcontroller)

15 pounds (a little heavy for lightweight, best for a middleweight)

125 rpm (perfect)

torque 125 I/P (fine for robot purposes)

shaft diameter is 0.83 inches with double flats (the flats are useful, but the diameter is odd).

overall dimensions are 14 inches long, diameter of motor is 3 inches, and the gearbox is about 4 inches high.

Another thing to note is that this motor has a hand brake that needs to be removed. Otherwise it is an excellent, low-cost middleweight motor. If you use them with a Vantec RDFR23 and two 3-5 amp-hour 12 Volt batteries you should have a reliable base to move around your ultimate weapon.

The second motor (NPC-31250) costs each,

General specs are

12 volts (you could use 24 volts for more power!)

30 amps peak, 7 amps continuous (use a Vantec RDFR23 speedcontroller)

7 pounds (perfect for a lightweight, OK for a middleweight)

65 rpm (125 at 24 volts)

torque 75 I/P (fine for robot purposes)

shaft diameter is 0.4345 inches, 1.5 inches long, with a pin hole already drilled a half inch form the end.

overall dimensions are 8.5 inches long, diameter of motor is 3 inches, and the gearbox is about 6 inches high.

This is the motor to get for a lightweight robot. If weight is a factor you can use just one 12 volt battery (3-5 amp hours life) but I would recommend that you double the voltage to get more power and speed out of this motor (65 rpm at 12 volts is a bit slow). The Vantec RDFR23 () should be fine for two of these motors, but as always there is always the risk of blowing your electronics, so be sure to put a 20 amp fuse in line.

If you want to order either motor contact

info@npcinc.com

or call 1-800-444-3528

and be sure to order 1 left-hand motor and 1 right-hand motor. Also, please note that these people do not answer uninformed questions. If you ask "dumb" questions you will not get a response. If you understand the info I have presented here and are interested in getting motors for your robot, then get your VISA card ready. Otherwise, read the rest of this tutorial!!

Building an Electric Powered Two Wheeled Robot

NOTE: I will eventually post pictures for every step. But for now I wanted to get the information out to you.

Overview

This is a step by step guide for building a two-wheeled, electric powered robot.

It is not a set of instructions for building a full-blown robot ready for battle, but it will teach you the very important basics.

The robot we will be building has a right wheel and a left wheel. Right and left motors are attached to the wheels. The robot will move forward, backward, or turn in place depending on how the two motor shafts spin.

A piece of electronics (called the speed controller) controls the speed and direction of the motors, which in turn control the speed and direction of the robot.

A smaller piece of electronics (called the radio receiver box) sends command signals to the speed controller.

An RC radio sends command signals through the air, to the radio receiver.

You hold the radio, sending commands to your robot.

General Supplies

Definitely go to WildeEVolutions and print out a copy of their catalog.

I'm sure you will refer to it many times.

I have found a lot of interesting hardware from

McMaster-Carr

Grainger

And for misc. electronics, check Digi-Key

If you are having a hard time finding something locally, check these places out because they will ship next-day air.

NEW!

Do you need small quatities of aluminum and steel? Check out my new Online Metal Supply Store!

Tools

You will need;

Set of screwdrivers,

Hand drill (cord or cordless) and a set of drill bits.

Ducktape

And patience.

If you need tools check out Craftsman or Harbor Freight.

We will start with the RC radio.

This is your only link to the robot. If you want to be a serious competitor then you are better off with a good radio and crappy robot then vice versa. You can always build a better robot later and you will still have that great radio.

How can I get that great radio? Ask a friend or family member if you can borrow theirs. Really. A radio costs bucks and you will blow plenty of money making mistakes building your robot. If you can save some money now you'll be able to afford mistakes later.

OK, no one will trust you with a radio and it's a long ways until Christmas. You will have to buy a radio. Check out local tag sales for RC toy cars. If you can find a working helicopter or airplane kit for sale cheap, grab it. An old helicopter radio will be perfect for now.

If you have to buy a new radio, check out;

Futaba

Tower Hobbies

Hobbies.net

Or, search for a Hobby Store near you.

You'll want to find at least a four channel "FM" or "PCM" radio (avoid "AM" unless on a budget). A good computer-radio for sale is the Futaba 6X Series.

For around you get the full package (receiver, batteries, chargers, and servos). Some hobby shops will give you a discount if you don't want the servos. You can probably get this package without the servos for just over .

[note: servos are positioning mini-motors with feedback]

If want to step it up, check out the Futaba U8 series. But it'll run you to .

If you are on a serious budget and you just want to fool around with RC stuff, you might want to buy this Airtronics 2 channel radio for about .

However, I cannot really recommend it because by the time you buy a receiver, batteries, and chargers, you might be up to and for just another you can get a much better radio with everything included.

On to the Main Event

By hook or by crook you got your hands on a radio. If you have the whole kit, you might have plugged in the servos and fooled around with them. Good. Maybe you read the users manual. Great.

We can start building a robot!

A standard electric battlebot is made up of five necessary and some optional parts.

Necessary

1. speed controller

2. battery

3. two motors

4. chassis

5. two wheels

Optional

1. armor

2. weapon

We will not be dealing with the optional parts for this exercise.

Building a competitive robot involves matching the proper motors with the proper batteries with the proper electronics.... blah blah blah. We're just going to buy the parts and put them together.

Speed Controller

I am taking a top-down approach to building a robot; starting with the most expensive items and working toward the cheapest. If you hit a financial stop, you will just have to save your money until you can buy the next item. In the meantime, you can still learn a lot from what you have already bought.

If you found a good deal on a radio you should have some money left over for your robot's most expensive part -the speed controller.

The speed controller controls the speed and direction at which the motor spins.

Pretty straight forward.

Think of a speed controller as a gate between the battery and the motors. The gate can be either closed, wide open, or anywhere in between. When that gate is closed, the motors are not running. As the gate opens, the motors start to turn. The wider the gate opens, the faster the motors turn, until the gate is completely open and the motors will not run any faster.

There are two types of speed controllers;

1. physical

2. electrical

Physical speed controllers are simple types of switches and can be a lot more reliable than electronic speed controllers. Electric speed controllers give you much better control over your drive motors and are usually more expensive than physical speed controls.

If you have the bucks, you will want to buy an electric speed controller.

For controllers, check out

Vantec

Tekin Electronics

Novak Electronics

If you can afford to spend get a Vantec RDFR23 speed controller.

It's a small, two-channel package and perfect for any robot 50 lbs or under. Two-channel means that it can control two motors independently. Vantec also supplies instructions for assembly.

If this is beyond your budget or you already spent your cash on a decent radio, there are options.

Most modern RC cars have single-channel electric speed controllers. Single-channel means that it can control only one motor. Since we are building a two-motor robot, we will need two of these single-channel speed controllers.

Unfortunately, they are not cheap. A good controller with ability to reverse (make the motor change direction), such as the Novak Rooster , will run about . So buying two will cost around .

For that amount of money you could buy the Vantec RDFR21 (similar to the RDFR23 but less power).

But for now, if this is too much, you can buy a cheaper electronic controller without the ability to reverse, such as the Explorer for about . Two of these will cost a total of .

However, without the ability to reverse you are severely crippling your robots mobility.

If you found a modern RC car kit at a tag sale or swap-meet, you might already have one of these types of speed controllers. If so, take it down to your local hobby store or check the web for a duplicate controller.

If this is still too much money for you to spend, there are other options. But you sacrifice controllability for low cost.

Team Delta sells a very nice relay system. A relay is an on/off switch that you can control electronically. With it, you can either turn the motor full forward, full reverse, or full stop. But there is no in between. A relay system is great for turning a weapon on and off, but not so great for turning drive train motors on and off. Your robot will be very difficult to control.

The price for one is , so two will cost . This is a pretty big savings over the single direction speed controller, but as I said before, your robot will be difficult to steer with just on/off control.

If you really want to save money you might have to use a physical speed control. A physical speed controller is essentially a swiper attached to a servo arm. But don't despair! At least you already have some servos that came included in your radio kit. And you will not have to worry about burning out any electronics with a physical system.

Older RC car kits used a physical system for speed control. Search everywhere for an old electric RC car. Even if it's junked, the mechanics for the speed control are probably good. If you can find two, great, otherwise you might have to build a second based on the first.

If you have the cash to blow, you can use what the big boys use -a Vantec RDFR38E. It'll run you around but you will be able to use it later for heavyweight robots. That is, if you don't blow it up.

Editor's Note:

There is a good chance you are broke by now. Do not worry.

You can get the rest of your robot parts pretty cheaply.

Batteries

You need a battery. For now, any 12 volt, 3 to 5 amp hour rechargeable battery will do and it should cost around . You will have to buy a small trickle charger, which will cost another .

If Radio Shack doesn't have what you need, try the following places;

Power Sonic

Web Battery

Hawker Energy

Hawkers are pricey, but have some of the best batteries.

You can also buy NiCad 9.6 volt battery packs from hobby shops. Nicads pack a lot of punch in a little bit of space, but I am suggesting standard sealed lead batteries for now because they will go longer between charges. But if you are interested, check out some of the on-line hobby shops I mentioned above as well as

Tekin Electronics

Novak Electronics

A couple notes: most competitive robots use many batteries at higher voltages.

Please remember that you are just getting started and the goal here is to learn.

One battery is fine. Be sure to get a recharging unit!

DC Motors

To continue this exercise you will need two permanent magnet DC motors.

Specifically,look for

-DC Gearhead motor rated for 12 to 24 volts

-Permanent magnet (not series wound)

-Weight 1 to 5 pounds

-Output Shaft

-60 to 120 output RPM

Try to find:

1. automotive power window motors

2. automotive windshield wiper motors

3. wheel chair motors.

Automotive motors are pretty cheap (around each for a windshield motor). Wheelchair motors are more expensive but much, much more powerful. A 50 lb robot powered by a wheelchair motor with a Vantech speed controller would be competitive. You can get rebuilt (used) wheelchair motors at National Power Chair.

Everest and Jennings Motor from National Power Chair

If you cannot afford wheel chair motors, try looking through

C&H Sales

All Electronics

American Science and Surplus

Herbach and Rademan

and I stronly suggest calling Surplus Center (1-800-488-3407) and getting a catalog today.

If you are forced to scrounge around and you find a mystery motor, check that

1. its casing is magnetized

2. it has only two wires coming out (or two connection points)

3. the motor shaft spins when you connect the wires to your battery and then the shaft reverses direction when you reverse the battery polarity (i.e. swap wires).

One final note: whatever motors you buy, please make sure that the output shaft rotates somewhere between 60 and 120 RPM's. That's one or two revolutions a second.

Benchtop Testing

Clear off some area on your desk. In that area place your

Single 12 volt, 5 amp hour rechargeable battery

Two right angle gearhead DC motors (preferably from NPC .)

Speed controller (preferably a single Vantec controller or two RC car controllers)

Radio

Radio receiver box and radio receiver battery.

Antenae, Receiver, and Battery

Put the battery on the table in front of you. On either side of the battery, place a DC motor with the shafts pointing out, away from the center. Try to keep the output shafts lined up along the same imaginary line. Wrap everything in duct tape to hold it all in place. It really works.

Get some wire, an on/off switch rated to 10 amps, a couple of inline fuse holders, and 10 amp fuses from Radio Shack or even a hardware store. You will also need some wire cutters and strippers.

Try Digi-Key for that stuff.

Using the speed controller directions, hook up the motors to the speed controller and then the battery to the speed controller. Somewhere between the battery and the speed controller include a fuse holder (with a 10 amp fuse!) and a power switch. Keep the switch off for now.

If you are using reversible electronic speed controllers (Vantec, Rooster) you should not in any way wire the battery to the motors. Like a gate, everything goes through the speed controller.

The last thing you need to do is plug in the speed controller signal wires (2 wires) into the receiver.

HINTS: if you are using a Vantec controller, you have one unit with two signal wires. These wires plug into channels 1 and 2 of your receiver. You also need to plug a battery into the receiver.

If you are using RC style controllers, you have two units with one signal wire apiece. Plug these into channels 1 and 3 of your receiver unit. You will not have to plug in a receiver battery.

Once you have everything hooked up to the speed controller according to instructions, you are ready to turn on your radio. But let's make one final check;

1. DC motor #1- both wires attached to the speed controller

2. DC motor #2- both wires attached to the speed controller

3. Negative battery pole attached to speed controller(s)*

4. Positive battery pole attached to switch

5. Switch attached to inline 10 amp fuse

6. 10 amp fuse attached to speed controller(s)

7. Speed controller(s) signal wire plugged into the radio receiver according to instructions

8. Radio receiver battery (NOT the robot battery from check 3 and 4) plugged into the radio receiver**

Receiver Battery, NOT main battery

*if you are using Vantec, all wire connections go to the single Vantech.

*if you are using a RC style speed controller (Rooster, etc), you will have one single-channel speed controller for each motor.

** battery not necessary if you are using RC car style single-channel speed controllers

Ready to Rock

Turn on your radio and then turn on the power switch.

One or both your motor shafts may start to slowly spin. Don't worry! Try adjusting the trim on your radio until the shafts stop turning.

Try moving your joystick. The motor shafts should turn.

Troubleshooting

For starters, go through checks 1 to 8 listed above.

If neither shaft runs then you probably have a problem with your robot battery or the receiver unit. If only one motor is spinning then you probably have a faulty connection between the dead motor and your speed control.

If neither motors turn;

1. Check the fuse

2. Check the power switch

3. Make sure the robot battery is fully charged

4. If you are using one, make sure the receiver battery is fully charged

5. If you are not using one, make sure you do not need a receiver battery

If only one shaft runs;

1. Check the battery connection to the speed controller

2. Check to make sure the bad motor is properly connected to the speed controller

3. Check to see that the signal wire from the speed controller is properly connected to the receiver.

Final Check

By now the motors should respond when you move your radios joysticks. A Vantec speed controller has single joystick mixing. As long as you have the Vantecs signal wires plugged into channels 1 and 2, both motors should respond to your radios right hand joystick.

If you push the joystick forward-- both motor shafts spin forward

If you push the joystick back-- both motor shafts spin backward

If you push the joystick to the right-- the left motor should spin forward and the right motor should spin back.

If you push the joystick to the left-- the left motor should spin back and the right motor should spin forward.

Moving the other radio joystick (left side) should do nothing.

If you are using RC car style controllers and the signal wires are plugged into channels 1 and 3, the right motor should respond to the right joystick and the left motor should respond to the left radio joystick.

If you push the right joystick forward-- the right motor shaft spins forward

If you push the right joystick back-- the right motor shaft spins backward

If you push the left joystick forward-- the left motor shaft spins forward

If you push the left joystick back-- the left motor shaft spins backward

If you move either the right or left joystick side to side, neither motor should spin

If your motors do not follow these rules, but BOTH your motors are responding in some manner, then fixing any problems from here on out will be simple. Try swapping the leads coming from the motor going to the speed controller until the above rules are true . If you are still having problems you might have to swap your signal wires.

Now What?

By now you are pretty anxious to get this mass of stuff and wires on the floor.

You need two things -chassis and wheels.

Well, maybe you do not need a chassis. If you did a good job wrapping up the motors, battery and speed controller in duct-tape you might not need a body, especially if you are using small DC motors and a light battery. Try lifting the big bundle up by the motor shafts. If nothing falls apart then you should go for it and not bother making a chassis -for now.

If you are using larger, wheel-chair style motors from National Power Chair or something similar, you will have to build some structure. Duct tape will not cut it.

Building the Chassis

Just about all gearhead DC motors have some sort of hole pattern. The trick is to make the simplest support for motors, battery, and speed controller.

I cannot give you advice on how to build a support system for every motor out there. I can only run you through one example. I am going to assume you bought two E&J RAE 24 Volt DC motors from National Power Chair. and give you some tips for building a chassis to support them.

1. Buy a piece of aluminum bar, 3 inches wide by 3/8 inch thick by 1 foot long from a local supply shop or at my Online Metal Distributor.

Steel would be fine, but harder to drill.

2. Take a magic marker draw a rectangle that is about 2 inches by 3/4 inches on both ends of the aluminum bar. Draw the rectangles so that the 2 inch side is about a half inch from the end of the bar.

Using the corners of the two rectangles, drill eight holes with a 3/8 diameter drill bit (use a cord or cordless drill). You should now have a foot long piece of aluminum with eight through holes, four on either end.

These will be your mounting holes for the E&J motors.

NOTE: if you have a similar style DC motor all you need do is draw a different sized rectangle that matches the mounting pattern of your motor.

Get a dozen 1/4-20 screws about 3/4 inch long (McMaster-Carr). Also get a variety of large hose clamps.

You should be able to bolt the motors to the bottom of the aluminum plate. Between the motors you should have enough room to hose clamp (or duct tape) the 12 volt battery to the aluminum bar. Find a place on top of the aluminum bar (away from the ground) to duct tape the speed controller, receiver box and battery.

You should now have a secure base. Run through the bench testing exercise (above) again to make sure everything is still working. All you need now are tires to make it a mobile base.

Tires

You have got this mass of stuff with two motor shafts sticking out in opposite directions. We bought gearhead DC motors around 60 to 120 rpms so we could attach two wheels directly to the motor shafts and not have to deal with any type of drive train.

Take a ruler and measure the distance from the motor shaft to the desk it is all sitting on. Double that distance and then add an inch. What you have found is the bare minimum wheel diameter you need to buy. For instance, my E&J DC motors measure about 4 inches from shaft to the ground. I need at least a nine inch diameter wheel.

Measure the diameter of the motor shaft. In my case it is a 1/2 inch diameter shaft.

If you can find a wheel that matches your required diameter and can fit right onto your motor output shaft you will be styling. In my case I need a 9 inch or larger diameter wheel with a 1/2 inch hole in the middle.

Try to find what you need at

Tires Unlimited

Northern

C&H Sales

All Electronics

American Science and Surplus

Realistically, you will not find exactly what you want. You will have to modify the wheel in some way or make something that goes between the wheel and motor shaft and you'll want to make it a very tight fit.

This sounds easier then it really is. If you do not have this type of experience see if you can find someone local to help you. You will save yourself a lot of head banging.

TIPS: Do not modify the motor drive shaft. It is easier (cheaper) to modify the wheel.

If the center hole of the wheel is smaller than the motor shaft, you could probably drill it out until you get a tight fit. Buy an extra wheel in case you screw up.

If the center hole of the wheel is larger that the motor diameter you might be able to find a pipe or tube that will fit between the large hole and the motor shaft.

If you want to learn about small tires go to the Infernolab's wheel comparison page.

YOU ARE REALLY READY TO ROCK!

Take your new creation outside (away from fragile things) and try running it around. If you properly bench tested it before putting on the tires you should have no problems.

You might find that some things are loose or even fall off. No sweat! Just duct tape it all up again. Congratulations! You have built your first robot!

Hey! What about a weapon!

The goal here was to get you familiar with the absolute basics. Once you understand the fundamentals you can build on them. In most cases it is more important to have a working mobile base then a weapon system. But I will give you a quick word of advice on building weapons.

You will find that a lot of weapons can be independent of the drive train. What you need to do is experiment with a weapon idea you like, make it, then bolt it down somewhere to your mobile base.

OK, I'll give you another hint. The best way to make weapon is to read about what other people tried to do on their websites. Go to the Robot DataBase and do a specific search on a weapon idea you like. If you like saws, do a search on all the robots that used saws. Or if you want to learn about pneumatic rams or pnematics in general, choose "pneumatics" under weapon power and then submit.

Good luck!

|

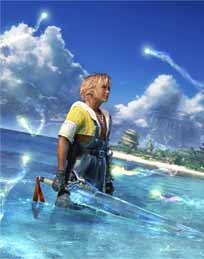

FF10 Screen

Tidus- Main character

Send an email |